Project Description

Repair Experience

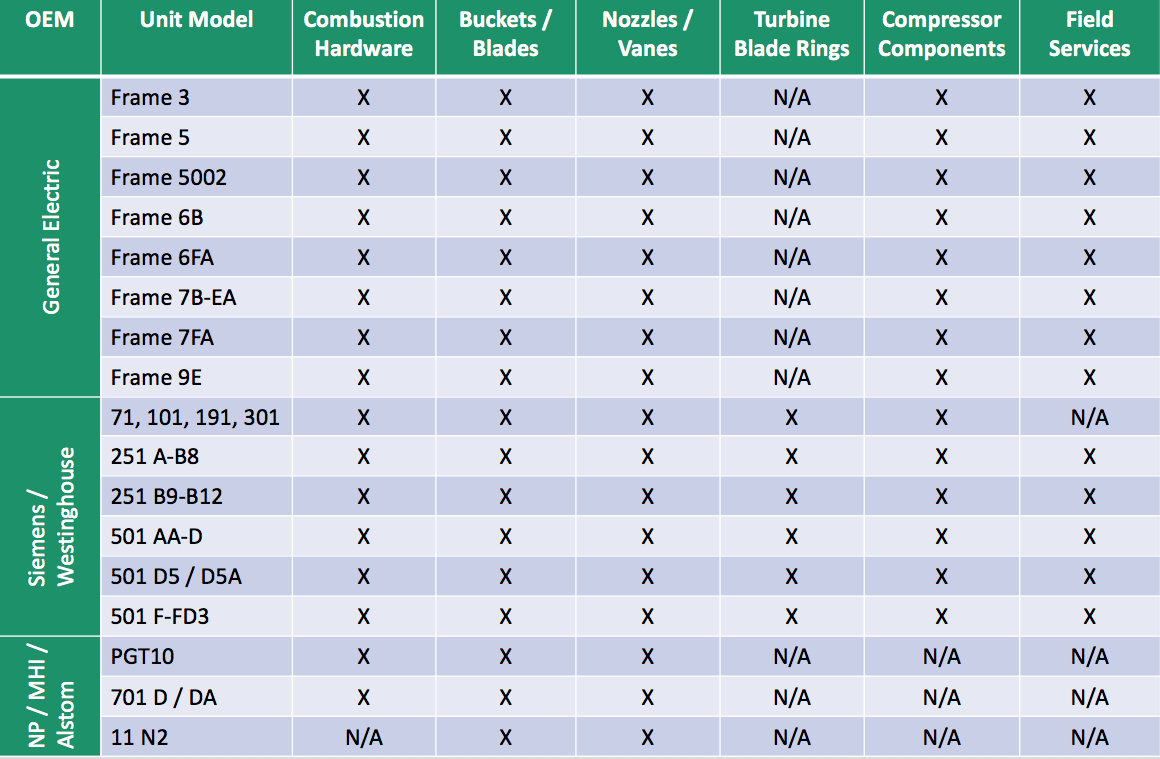

The staff of Trinity Turbine Technology, LP has decades of combined experience with all GE and Westinghouse mature frame gas turbine component repair and coating processes. We also have experience with other manufacturers including Mitsubishi, Siemens, and ABB. We have compiled the finest staff of engineers and component repair specialists in the industry. We have full experience with all components including buckets and blades, nozzles and vanes in addition to all styles of combustion components. We also have extensive experience with compressor diaphragms and other miscellaneous components such as shroud blocks, blade rings, ring segments, inner stage seals, inner barrels and support rings. Our component repair experience ranges from mature IGT models to newer F class units with proven processes and tooling. With our capabilities and experience, we can develop innovative repair solutions for many other models of gas turbine components as well. We would appreciate the opportunity to add you to our growing list of satisfied customers. Call Trinity Turbine Technology, LP first.

World Class Facilites

Our new home is a custom 85,000 square foot facility conveniently located just south of Houston on 288 North. Within the walls of this office we offer many cost effective and reliable services including:

- Advanced Coatings

- Superior Quality Component Repair For Gas & Steam Turbines

- Field Service Operations

- New & Refurbished Capital Spare Parts

Come visit us and tour this one stop shop for all your needs.