Project Description

Rotating Components

At Trinity Turbine Technology L.P. we believe that component testing is the most crucial element of the repair and coating process. In order to ensure that the repaired components will fit and function as designed, meticulous attention to detail must be utilized to verify that the components meet all the specified requirements.

To support this, we have developed comprehensive in-house component testing procedures including penetrant, eddy current, ultrasonic and flowtesting. In addition, we have an extensive list of highly accurate fixtures and gages to ensure that the repaired components will not only fit properly in your machine, but also perform as it was designed.

When you need to know that your components will be repaired properly, call Trinity Turbine Technology first!

Buckets & Blades

Z Notch Restoration

Tip Restoration

Moment Weigh Inspection

World Class Facilites

Our new home is a custom 85,000 square foot facility conveniently located just south of Houston on 288 North. Within the walls of this office we offer many cost effective and reliable services including:

- Advanced Coatings

- Superior Quality Component Repair For Gas & Steam Turbines

- Field Service Operations

- New & Refurbished Capital Spare Parts

Come visit us and tour this one stop shop for all your needs.

Rotating Components are among the most critical found in a gas turbine. The repair procedures utilized by Trinity Turbine Technology, LP are designed to restore the Mechanical Integrity of the alloys while ensuring Dimensional Accuracy. Our team of engineers and highly skilled repair technicians are the best in the business at safely maximizing the life cycle of your buckets and blades. We routinely extend the useful life of rotating components well beyond the OEM recommendation without a single failure. Let us help you minimize your maintenance costs by safely extending the life of your Rotating Components.

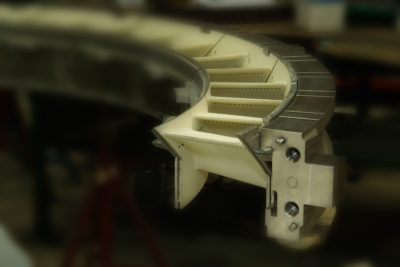

Rotating Components are among the most critical found in a gas turbine. The repair procedures utilized by Trinity Turbine Technology, LP are designed to restore the Mechanical Integrity of the alloys while ensuring Dimensional Accuracy. Our team of engineers and highly skilled repair technicians are the best in the business at safely maximizing the life cycle of your buckets and blades. We routinely extend the useful life of rotating components well beyond the OEM recommendation without a single failure. Let us help you minimize your maintenance costs by safely extending the life of your Rotating Components. Performing highly accurate Z Notch Restorations is just one of many ways that Trinity Turbine Technology, LP can increase the useful life of your Rotating Components.

Performing highly accurate Z Notch Restorations is just one of many ways that Trinity Turbine Technology, LP can increase the useful life of your Rotating Components.